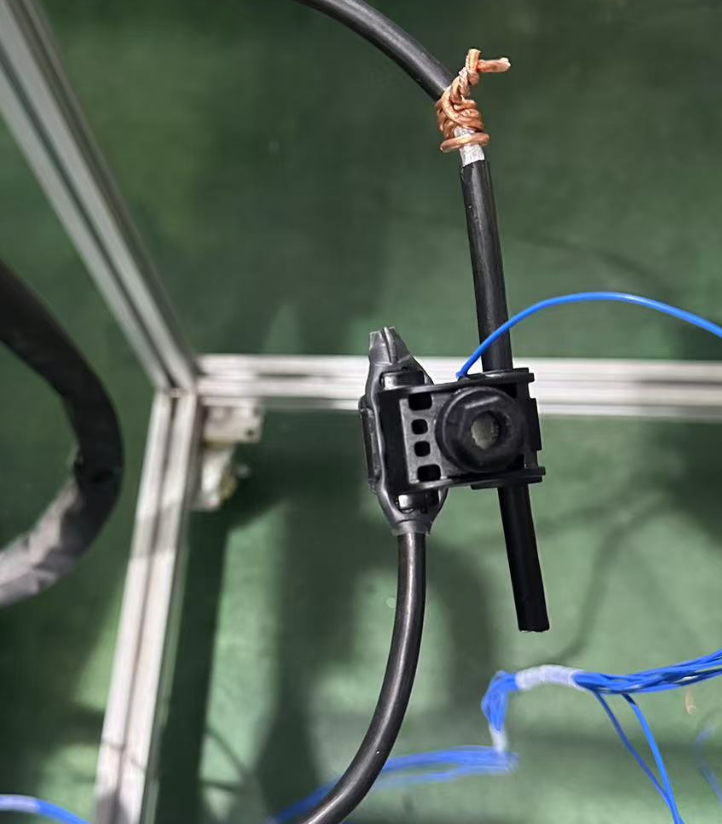

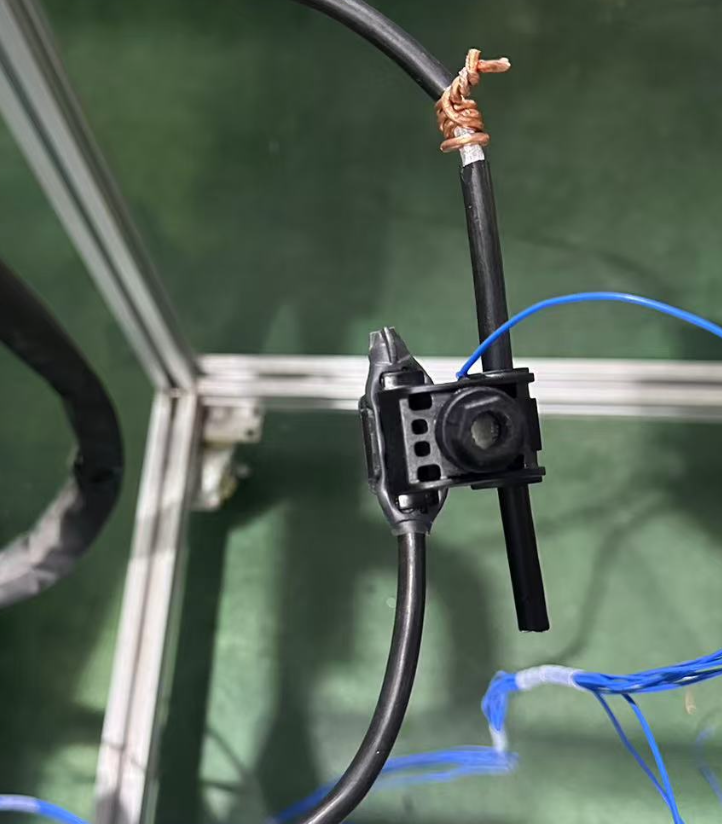

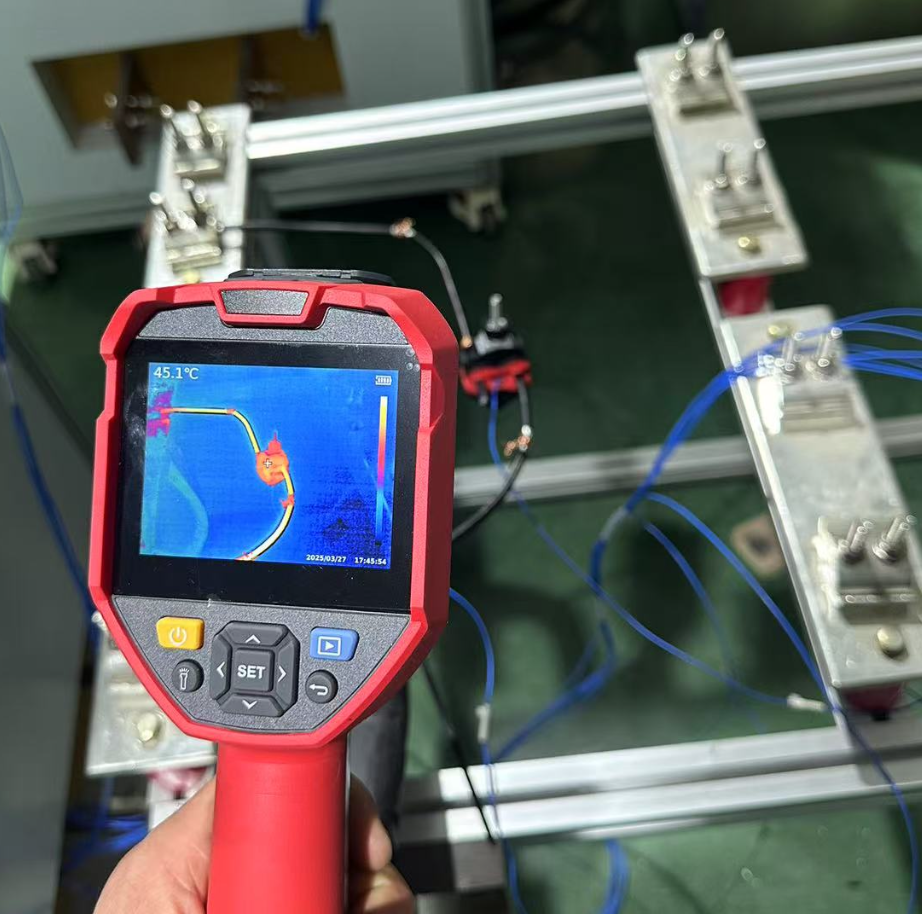

Jera Line on-site laboratory has the thermal imaging camera testing machine for insulation piercing connectors, A thermal imaging camera is a non-contact diagnostic tool used extensively in electrical and mechanical inspections. Its main use in electrical systems is to spot hot spots—places that are hotter than they should be. These hot spots can show there's a problem like loose wires, corroded contacts, or overloaded parts.

Using for Hot Spot Connection Testing:

The camera visualizes temperature variations by capturing infrared radiation emitted from components, revealing areas where electrical resistance causes localized heating.

Detects developing faults before they lead to failure or outages, allowing maintenance to be planned proactively.

Visualizes the resistance at connection points, ensuring they are within safe operational limits.

Advantages of Using a Thermal Imaging Camera:

Inspections are quick and do not require physical contact, making it safe and convenient.

Provides immediate thermal images for accurate assessment.

Enables inspection of large systems and complex connections efficiently.

Helps in planning repairs and avoiding equipment failure, reducing downtime and repair costs.

Test procedure:Test duration 60 mins of main and tap cable under 95A, temperature 75 C, heat the master cable by cycles to 75C, after cooling on 30 sec,

Test result: See the difference of cooling curves of IPC, with different teeth, and size.

Tested products:

Please feel free to contact Jera Line if you have any questions.