Stainless steel bands are commonly used in a variety of applications, including industrial, construction, and electrical works. Here the stainless steel band is considered to use with overhead power cable fittings, to deploy the low and medium voltage power cables.

The main manufacturers of stainless steel bands include:

· Band-It (a division of IDEX Corporation), USA.

https://www.band-it-idex.com/products/band-buckle/

Location: Denver, Colorado, USA

Overview: Band-It is one of the most recognized names in the industry, known for producing high-quality stainless steel banding and clamping solutions. Their products are used in a wide range of industries, including aerospace, automotive, and energy.

Products: Stainless steel bands, buckles, clamps, and installation tools.

Specialization: They offer customized solutions and have a strong global presence.

· PANDUIT, USA.

Location: Tinley Park, Illinois, USA.

Overview: A global manufacturer of physical, electrical, and network infrastructure solutions. PANDUIT produces a range of stainless steel bands used in different sectors, including electrical and telecommunications.

Products: Stainless steel banks in different steel grades.

Specialization: They focus on electrical network infrastructure solution.

• Bandimex Befestigungssysteme GmbH is a German company founded in 1982.

Corporate Information – Bandimex Befestigungssysteme GmbH

It specializes in manufacturing and supplying universal hose and pipe clamps, as well as band clamping systems.

The company is headquartered in Wilnsdorf, Germany.

Bandimex has developed into an internationally active company, with its products being used in various industries worldwide. They are known for their high-quality stainless steel bands and clamping systems, such as stainless steel band, buckles, steel ties.

· Jera Line. China.

Location: Yuyao, Ningbo China

Overview: Jera Line is a that specializes in producing stainless steel bandings, among other products. They are known for their high-quality manufacturing processes and serve a variety of industries globally. Jera Line likely offers a range of banding solutions that meet international standard ASTM G108-94(2015), catering to industries like telecommunications, energy, and construction.

What seria stainless steel banding Jera Line has?

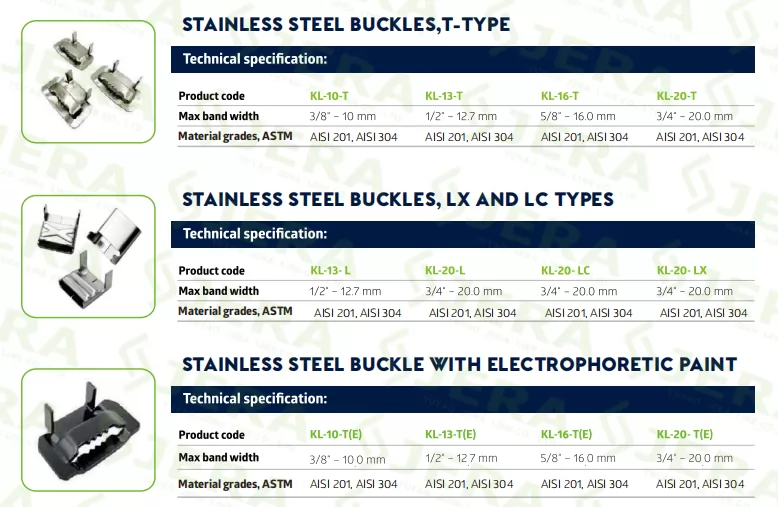

JERA LINE provide stainless steel banding solution, including products as below:

Stainless Steel Bandings: Stainless steel bandings is also called stainless steel straps are used to secure and bundle items such as cables, pipes, and hoses. These straps are available in different widths, thicknesses, and grades of stainless steel to accommodate various load capacities and environmental conditions.

1. Self tightening tie

Including Perforated Stainless Steel Band and Stainless Steel Cable Ties

1. Banding accessories

Including Stainless Steel Buckles and tool

How to distinguish stainless steel grades?

|

Grade |

Chemical component Ni content |

Remarks |

|

J201 (C430) |

Ni 1.0-1.2% |

Chinese standard J201 grade (analog 430) |

|

C201 |

Ni 3.5-5-5% |

International standard 201 grade |

|

Ni >= 8% |

Most widely used stainless steel, good corrosion resistance |

|

|

C316 |

Ni <10% |

enhanced corrosion resistance |

Jera Line has a Testing equipment in laboratory: Metal Spectrometer XRF VATANA, which can analytical technique that examines the elemental composition of materials.

It can ensuring the grade of stainless steel we supplied is fit what customers request.

Meanwhile Jera Line also controls the raw materials by XRF gun, to ensure the quality control of products

What tests of Stainless steel banding Jera Line can provide ?

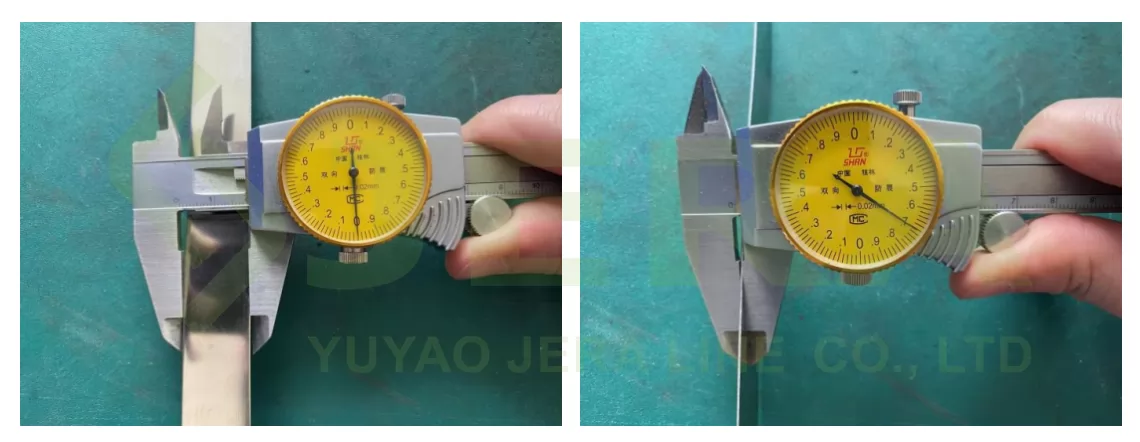

1.Band dimension

2.Chemical component test

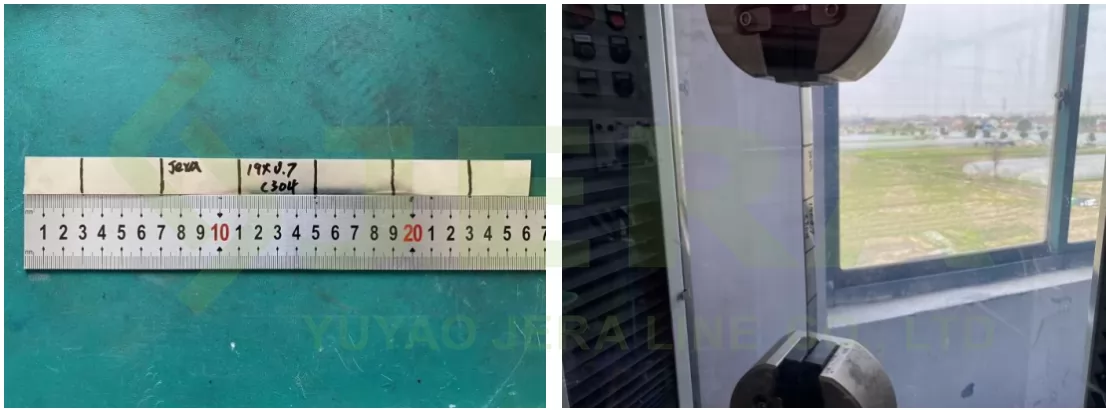

3.Tensile strength and elongation test

Understand testing of tensile strength and elongation

Tensile strength, the maximum stress a material can withstand while being stretched, links closely to elongation, which is the degree of deformation before failure. A balance between these properties is key for many applications—materials too brittle may crack under stress, while those too ductile may not offer enough support. Therefore, analyzing both tensile strength and elongation during testing provides a comprehensive overview of a material's performance under tension, helping predict its behavior in real-world conditions and ensuring its suitability for specific purposes.

Jera Line’s bandings are passed tensile strength and elongation test, which has good performance in real applications.

Why Jera Line is competitive?

Jera Line as your stainless steel banding supplier, can provide the following advantages:

Material Standards: Jera Line adheres to strict international standards for stainless steel production, ensuring that their banding products are durable, corrosion-resistant, and reliable.

Variety of Options: Jera Line offers a wide range of stainless steel banding products, including various widths, thicknesses, and finishes to meet the specific needs of different industries.

Cost-Effective Solutions: Operating as a leading factory in China, Jera Line can offer competitive pricing without compromising on quality. And Purchasing directly from the factory eliminates middlemen, which can further reduce costs.

Excellent Customer Support: Jera Line provides technical support to help customers choose the right products for their specific applications.

Customization and Flexibility: Jera Line offers the flexibility to provide tailored solutions that meet your specific requirements, whether you need a particular size, grade, or finish of stainless steel banding.

Customer Satisfaction: Positive feedback and strong references from existing customers highlight Jera Line’s commitment to quality and service, making them a reputable choice in the industry.

More information please check our YouTube Channel.

Welcome to contact us!