The TTD051FJ2TA is one brand model of insulation piercing connector, designed for low-voltage aerial bundled cable (ABC) systems.

The insulation piercing connector (IPC) is a crucial component that ensures strong, durable, and efficient electrical connections between two conductors. It features an integrated connection without stripping the insulation of the conductors, ensuring a reliable service life while causing controlled damage to achieve an effective connection.

The TTD051FJ2TA is a part of this IPC family and serves as a key component in electrical connections for overhead power lines, used for 16-95 mm² cross-sectional area cables.

As a leading manufacturer specializing in low-voltage (LV) and medium-voltage (MV) cable connections, Jera Line develops and produces a wide range of IPCs, for the following applications:

Jera Line’s ZOP-45 and ZOP-45P are designed for small cross-section cables, and their functionality can cover the applications of TTD051FJ2TA.

|

Item No. |

Main conductor mm² |

Tap conductor mm² |

Torque N*m |

Conductor type |

|

4-120 |

1.5-16 |

11 |

Al and Cu |

|

|

4-70 |

1.5-16 |

5 |

Al and Cu |

|

|

TTD051FJ2TA |

16-95 |

1.5-10 |

9 |

Al and Cu |

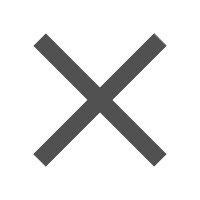

Jera Line shot a video of the installation steps for the ZOP-45P: How to connect the EV Charger, outdoor street lightning power cable by piercing connector ZOP-45P

Step 1: Insert the main and tap conductors into the groove of IPC.

Step 2: Tighten the shear head bolt, until is has been sheared off.

Step 3: When the bolts have sheared off and the metal teeth penetrate the conductor, the connection has been established.

Step 4: Check the connection status and energize the circuit.

As you can see, it is quite easy to install and can be done by just one experienced worker. During installation, you can use Jera Line’s Holding tool JTN-7 to hold the IPC for safer installation without direct human contact. Jera Line’s dielectric torque wrench JTN-11-13 can be used for tightening the bolts (for ZOP-45).

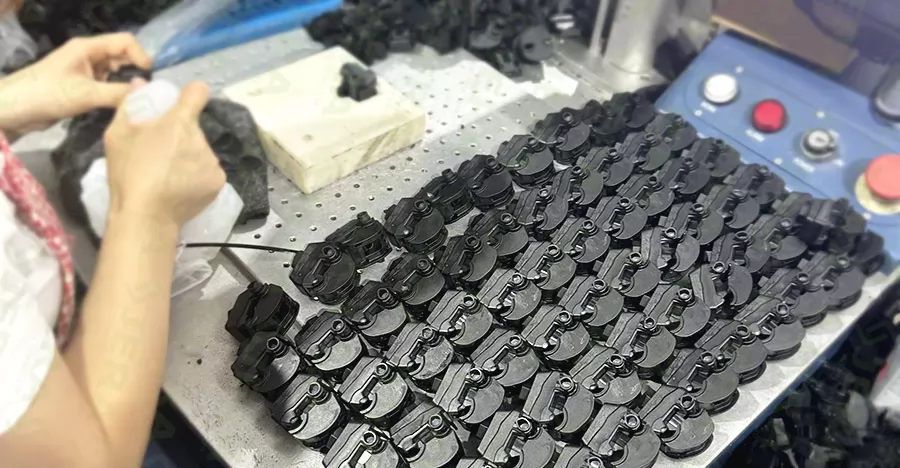

Jera Line is a manufacturer located in China, with a facility area of over 5,000 square meters. Jera Line’s production area includes:

Jera Line’s IPCs comply with international standards, such as EN-50483-4 and NF C 33 020. Many types of IPCs own the third-party test reports. Jera Line also established its own in-house laboratory to verify short-circuit overcurrent performance and temperature & humidity aging resistance for IPCs.

Jera Line’s quality and cost control starts at material integration. Understanding “How can we match materials with product applications?” directly affects product quality and production efficiency.

We must verify that the quality, specifications, and quantity of the raw materials align with the product's requirements.

Jera Line continues to develop new products for cable accessories. All our existing insulation piercing connectors (IPCs) are of A1 Class, and we are actively researching B2 Class IPCs. Furthermore, Jera Line is committed to promoting new products across the entire cable accessory market, not just for IPCs.

Jera Line offers OEM and ODM services to customers. We are open to using customers' logos or brands. Meanwhile, we are happy to develop new products in collaboration with our customers. It would be helpful if customers could send samples for reference in terms of quality and design.

Jera Line is a factory with global experience, with a strong ability to embrace new ideas. It has independent research and development capabilities, a professional team, and attentive after-sales service, it makes it an excellent partner for foreign trade cooperation.

Please feel free to contact us if you have any inquiries!